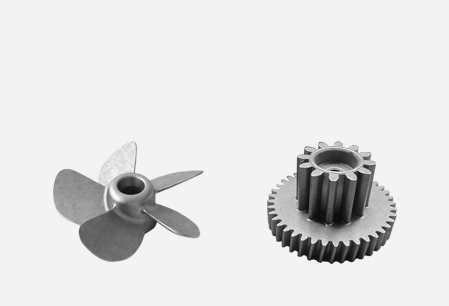

Precision CNC Machining Services

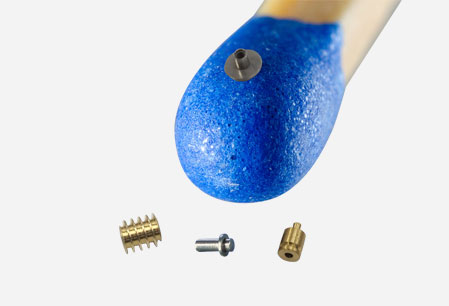

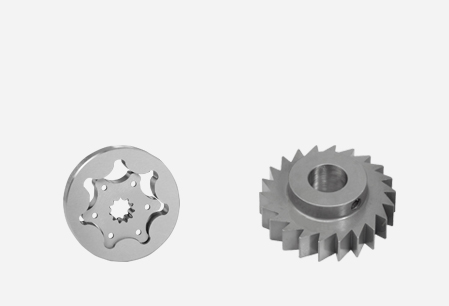

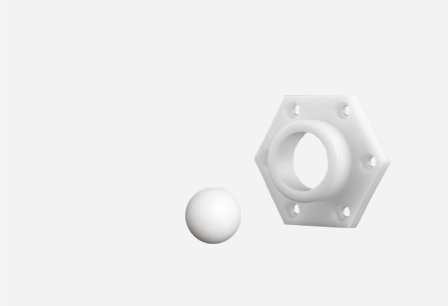

As a leading company in precision cnc machining services, we provide a large variety of custom-made products, plastic or metal, utilizing prototype machining to best suit the needs of the client. Over time, working alongside the medical, automotive, and defense services industries we have encountered numerous machining challenges, transforming us into unparalleled experts. Our primary goal is to provide our clients with competent and proficient services and consultation, as we are always happy to explore new and challenging CNC machining projects.

Whether you have a complete design or you are still in mid-process, our precision cnc machining services specialists are ready to provide you with their insight on the materials and designs that best meet your manufacturing goals. It is highly important to us to give each project attention and support per its individual requirements and needs, as we always keep in mind that each project is one of a kind. In order to provide you with the best solution, we offer machining services that meet your schedule and budgetary needs and have the specifications and tolerances you desire.

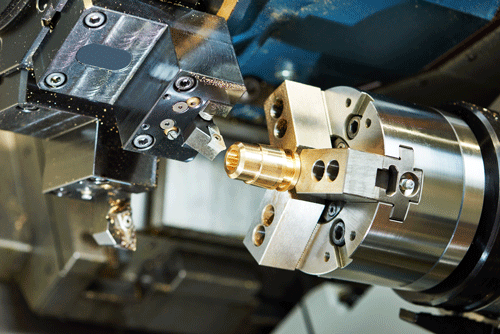

Using technologically advanced machines allows us to accommodate a large number of custom projects, while each step of the process is carefully monitored by our quality department.